Did you know that wildfires have doubled in frequency in the last 20 years, causing billions in losses and highlighting the urgent need for safer building materials? As climate change accelerates, homeowners, architects, and city planners are racing to find innovative ways to protect communities. Hempcrete construction—a revolutionary blend of hemp hurd, lime binder, and water—is emerging as the ultimate natural building solution. In wildfire-prone regions, this game-changing material stands unscathed where traditional buildings fail. In this article, you'll discover why hempcrete is rapidly becoming the gold standard for sustainable, resilient, and carbon-friendly construction.

A Startling Shift: Wildfires, Building Materials, and the Urgent Need for Hempcrete Construction

The past two decades have witnessed a startling increase in wildfires. Across the United States and other fire-prone regions, these natural disasters are more frequent, more intense, and devastating to communities built with traditional materials. Standard homes constructed from wood, steel, or concrete struggle to withstand extreme heat, suffering catastrophic losses and costing billions in property damage. As a result, the building industry is under immense pressure to innovate—not just to rebuild, but to reimagine safety for future generations.

Amidst this urgent search, hempcrete construction stands out as a sustainable alternative, offering unmatched fire resistance and environmental benefits. This shift is not just about survival—it's about embracing a future where eco-friendly building materials like hempcrete reduce vulnerability and offer hope for climate resilience. Whether you're a homeowner in a wildfire danger zone or a green-minded architect seeking next-level performance, understanding hempcrete’s advantages could reshape the future of your next building project.

"Wildfires have doubled in frequency over the last two decades, costing communities billions and leaving a trail of devastation through conventional buildings." — Institute for Disaster Resilience

What You'll Learn About Hempcrete Construction

The key components and science behind hempcrete construction in modern sustainable design

Why hempcrete outperforms traditional building materials in fire resistance

How hempcrete construction contributes to carbon sequestration and eco-friendly building

Practical applications and real-world case studies in the building industry

Answers to common questions about building with hempcrete and its future potential

Conventional Building Materials: Limitations in Fire-Prone Environments

The Rise of Wildfires and the Building Industry's Challenge

The relentless surge in wildfires—driven by rising temperatures, drought, and changing land use—has exposed critical flaws in many commonly used building materials. Wood, once the backbone of residential construction, is highly flammable. Steel, while resistant to ignition, can lose its strength and warp at extreme temperatures. Even concrete, often considered sturdy and reliable, can fracture and degrade when repeatedly subjected to intense heat. For architects, builders, and families, these well-known risks have forced a reckoning with the status quo.

Faced with actual fire tests and real devastation, the building industry increasingly recognizes that old standards are failing. Today, designing for fire resilience is no longer a luxury—it's a necessity, especially in areas like California and Australia where wildfires are now an annual threat. Seeking new solutions, some pioneers are turning to alternative building products that promise durability, safety, and sustainability, with hempcrete blocks leading the charge in the new era of natural building materials.

Performance of Building Materials Like Wood, Steel, and Concrete

Traditional building materials each have their strengths, but in wildfire settings, they reveal noteworthy limitations. Wood combusts easily and can fuel fires, steel—although inflammable—melts at high temperatures, and concrete may spall, releasing toxic dust and losing integrity. The deficiencies of these conventional materials are pushing the building industry to seriously reconsider what a safe, fireproof home should be constructed from. As a result, industry leaders are advocating for sustainable alternatives with proven performance in fire tests.

This challenge creates space for materials like hempcrete blocks, which inherently resist ignition and maintain their properties under thermal assault. Not only does hempcrete construction deliver genuine fire resistance, but it also supports environmental goals—a double win in this era of climate uncertainty. As more natural disasters test our infrastructure, the search for resilient building materials with superior fire resistance grows ever more vital.

"Traditional materials often fail against extreme heat and wildfire — prompting the building industry to reconsider safe alternatives." — Dr. Angela Lin, Sustainable Materials Specialist

Hempcrete Construction: What Is Hempcrete and How Does It Work?

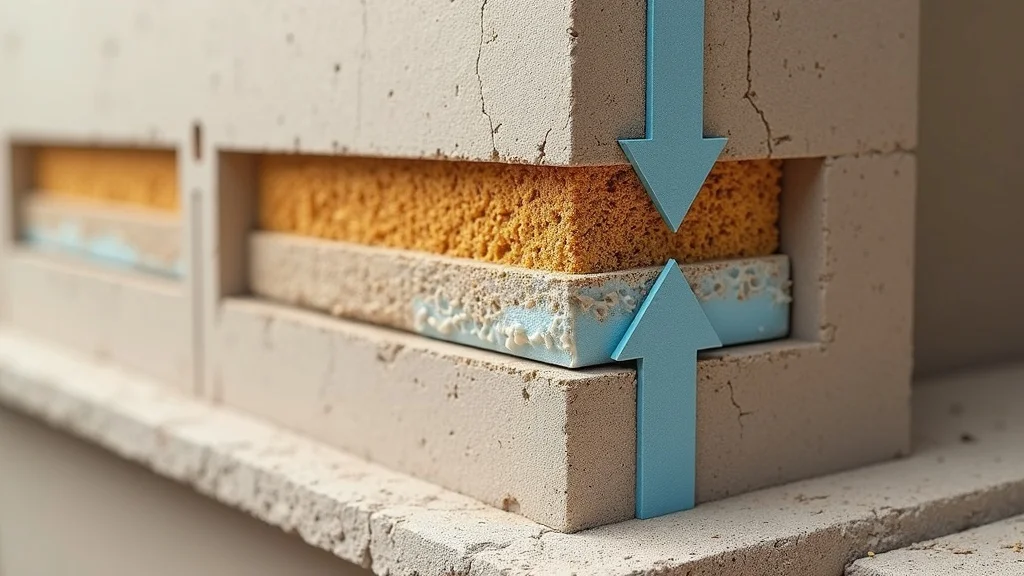

The Components: Hemp Hurd, Lime Binder, and Water

Hempcrete is a natural building material formed from three key ingredients: hemp hurd (the inner woody core of the industrial hemp plant), a lime-based binder (often hydrated lime), and water. The combination creates a lightweight, breathable, and highly insulative composite. Hemp hurd is prized for its high silica content and absorbent texture, which allows it to bond effectively with the lime binder. The lime, acting as a strong mineral matrix, not only sets hard but also preserves the natural properties of hemp while enhancing fire resistance and mold prevention. Once mixed, these components form a moldable paste that is cast into forms or sprayed onto structural walls, quickly curing to create robust hempcrete blocks ideal for low-carbon, sustainable construction.

This versatile formula leverages the best attributes of each ingredient—renewability, natural insulation, and fire resistance—giving hempcrete construction impressive advantages over traditional materials. Because it's made from hemp, a crop that grows quickly with minimal input, and uses a mineral-based lime binder, hempcrete delivers not only environmental benefits, but also tangible improvements in safety and indoor air quality for building projects of all scales.

The Process of Building with Hemp and Forming Hempcrete Blocks

Building with hempcrete starts at the farm, where industrial hemp is grown, harvested, and processed to separate the inner hemp hurd from the fibrous outer stalk. The clean hurd is then mixed with water and lime binder at the construction site. Builders either cast the wet mix into wall forms for custom shapes or use pre-molded hempcrete blocks for faster installation. After curing, the result is a solid, yet lightweight, non-structural infill that is both rigid and resilient. Hempcrete is typically paired with a **structural frame**—often timber or steel—since its compressive strength isn’t typically suitable for **load bearing** of multi-story structures on its own.

The construction process is relatively straightforward and eco-friendly. Unlike concrete—which creates massive carbon dioxide emissions when manufactured—hempcrete construction captures more CO₂ than it emits, thanks to the carbon sequestration abilities of the growing hemp plant. Each step, from cultivation to installation, is designed to minimize waste and maximize the durability and sustainability of the finished structure, making it an ideal fit for both residential and commercial green building projects.

How Hempcrete Differs from Other Building Materials

While conventional building materials like wood and concrete have been mainstays, hempcrete carves out a place of its own thanks to its truly unique properties. Unlike wood, hempcrete does not ignite or sustain fire even when exposed to direct flame. In contrast to concrete or brick, it is significantly lighter and offers remarkable insulation against heat and cold. Its open-pore structure allows for natural humidity regulation, helping to prevent mold and rot. The lime binder in hempcrete also gives antimicrobial qualities, resulting in a healthy, allergy-resistant living space.

Perhaps most notably, hempcrete blocks continue to absorb and store carbon dioxide throughout their lifespan, locking away atmospheric CO₂ and actively combatting emissions from the building industry. By embracing building with hempcrete, stakeholders can expect high performance in fire resistance, improved thermal properties, carbon sequestration, and an all-around safer, more sustainable building product.

Comparison of Hempcrete vs. Traditional Building Materials |

||||

Property |

Hempcrete |

Wood |

Steel |

Concrete |

|---|---|---|---|---|

Fire Resistance |

Unburnable, survives 1,000+°C |

Highly flammable |

Melts/warps at high temps |

Spalls/cracks under fire |

Carbon Footprint |

Negative (captures CO₂) |

Neutral or negative (depends on source) |

High emissions |

Very high emissions |

Insulation Value (R-Value) |

2.1–2.4/inch |

~1.25/inch |

Very low |

~0.08/inch |

Compressive Strength |

Moderate (non-structural alone) |

Moderate |

Very high |

High |

Sustainability |

Rapidly renewable |

Variable |

Resource-intensive |

Resource-intensive |

The Science of Hempcrete Construction: Fireproof and Eco-Friendly

Thermal Properties and Fire Resistance of Hempcrete Blocks

Hempcrete blocks are widely celebrated for their outstanding fire resistance and superior insulation performance. Unlike wood, which can stoke and spread flames, or concrete that may crack after prolonged exposure to heat, hempcrete forms a protective thermal barrier when subjected to high temperatures. Lab tests and real fire scenarios demonstrate that walls built with hemp hurd, hydrated lime, and water remain structurally stable, emitting no toxic gases and resisting combustion even at temperatures exceeding 1,000°C. This incredible property makes hempcrete construction an ideal candidate for wildfire-prone locations, offering peace of mind where it’s needed most.

In addition to fire resistance, hempcrete blocks excel at providing consistent indoor climates year-round. Their unique structure, composed of tiny air gaps within the hemp shiv and lime binder mixture, prevents heat from penetrating or escaping too quickly. This high thermal performance translates directly into lower energy consumption, reduced heating and cooling costs, and a lower environmental footprint. For anyone focused on safety, comfort, and sustainability, the choice to use hemp as an insulation material is a forward-thinking one.

Carbon Dioxide Sequestration in Hempcrete Construction

One of the most revolutionary aspects of hempcrete construction is its role in direct carbon sequestration. Industrial hemp plants, from which the hemp hurd is sourced, are among the best natural material choices for absorbing atmospheric CO₂ as they grow. When hemp is harvested and incorporated into buildings as hempcrete blocks, much of the carbon dioxide remains locked within the material—effectively removing it from the atmosphere for decades or even centuries. The lime binder further accelerates this process by gradually absorbing and reacting with ambient CO₂ during its curing phase, which adds to the overall carbon-negative footprint of hempcrete construction.

This dual mechanism results in life-cycle emissions for building with hempcrete that are not just low, but often net negative when compared to traditional concrete or steel-based buildings. With every hempcrete building project undertaken, the construction industry takes a substantial step toward climate restoration and sustainable building, fulfilling both environmental mandates and green certification requirements sought by today’s forward-thinking property owners.

Energy Efficiency and Indoor Air Quality Improvements

Hempcrete blocks deliver more than just climate resilience and fireproofing—they create homes and offices with exceptional energy efficiency and healthy indoor air quality. Thanks to their porous structure, walls built with hempcrete naturally regulate humidity and allow moisture vapor to escape, greatly reducing the risk of mold growth and chemical pollutants inside. This property is especially valuable in green building projects committed to occupant wellness and long-term sustainability.

Paired with its excellent insulation value—surpassing many synthetic or fossil-fuel alternatives—hempcrete minimizes the need for mechanical heating and cooling systems, saving energy and associated costs over the building’s lifetime. The end result is a natural building solution that offers tangible benefits in comfort, savings, and air quality, reinforcing the reputation of hempcrete construction as an across-the-board sustainable alternative.

Life-cycle emissions of hempcrete blocks compared to concrete and steel

Fire resistance test data for hemp building products

Case studies from natural building projects

"Hempcrete construction can withstand temperatures exceeding 1,000°C, remaining inert and non-toxic throughout wildfires." — EcoBuild Magazine

Building with Hempcrete: Real-World Applications and Success Stories

Case Study: Hempcrete in Wildfire-Prone California Residences

Nowhere is the promise of hempcrete construction more relevant than California, where wildfires have become an annual ordeal. One notable residential project saw a family home, built entirely with hempcrete walls and lime render, standing virtually untouched after a wildfire swept through the region, while neighboring timber structures were lost. Not only did the hemp block walls remain structurally whole, but the interior air quality and insulation were unaffected, even after intense heat exposure. In follow-up air quality tests, the home reported zero toxic particulates—demonstrating the real-world value of hempcrete’s natural and resilient properties.

This case, now widely discussed in green architecture circles, is sparking growing interest among builders and property owners in wildfire-prone regions. By choosing building with hempcrete, these pioneers are setting a new benchmark for both environmental stewardship and community safety. The momentum is unmistakable: as more successful outcomes like this come to light, the push for broad adoption across the building industry gathers steam.

Commercial and Industrial Uses: A New Standard in the Building Industry

Beyond private residences, hempcrete construction is also gaining traction in schools, community centers, and industrial facilities. Commercial builders are finding that hempcrete’s quick installation process, low maintenance needs, and superior fire resistance make it an attractive upgrade over traditional materials. The improved insulation and air quality, combined with measurable carbon sequestration benefits, are helping these projects meet and exceed green building certification requirements worldwide.

In large-scale construction sites, the transition to hemp building products is producing not just safer, but more comfortable and efficient environments for occupants and workers. From energy savings to a lighter environmental impact, hempcrete blocks are setting new standards in what modern sustainable building really means—solidifying hempcrete’s reputation as the material of choice for the new generation of industry leaders.

Inside a Hempcrete Home: Tour and Owner Insights

Challenges, Downsides, and Lessons Learned in Hemp Building

Despite its many strengths, hempcrete construction does have a few practical limitations. First, hempcrete’s compressive strength, though suitable for non-load bearing infill, means that traditional frames—usually wood or steel—are still required for structural support in most modern buildings. This makes it less suitable for very tall or heavy structures without careful engineering. Additionally, finding hemp building contractors with specialized experience can be a challenge, as hempcrete is still an emerging material in many markets, especially outside Europe.

Lessons learned from early adopters emphasize the importance of proper material proportioning, optimal curing, and understanding the regulatory environment. For some, the up-front costs can be higher than wood or concrete, but these are often offset by lower operational costs and the intrinsic value of a safer, greener, and more resilient home or commercial space. As technology and expertise mature, more builders are successfully navigating these challenges and reaping the long-term benefits of building with hempcrete.

Cost, Scalability, and the Future of Hempcrete Construction

Is Hempcrete Cheaper and More Accessible Than Concrete?

When first compared, hempcrete construction may appear costlier than traditional concrete due to limited supply chains and the novelty of the product in the United States market. However, a closer look reveals a more nuanced picture. The upfront costs of raw materials—specifically the processed hemp hurd and lime binder—may be slightly higher, but these are counterbalanced by lower labor costs (thanks to faster installation) and long-term savings from outstanding insulation and energy efficiency. Over the life cycle of a building, hempcrete’s maintenance and utility savings can far exceed any higher initial spend, making it a compelling value proposition for eco-friendly and fire-resilient construction.

Accelerated adoption and growing acceptance in the building industry are bringing down costs. More suppliers, increased production of industrial hemp, and streamlined building codes are making hempcrete blocks more accessible year-on-year. In some jurisdictions, incentives and grants are available for those who choose to build with sustainable alternatives—further tipping the scale in favor of building with hempcrete.

Scalability of Hempcrete in Large-Scale Building Projects

Scalability is no longer a concern in the hempcrete construction sector. Thanks to advances in agricultural production and building technology, it is now possible to source large volumes of industrial hemp needed for big projects. Automated mixing and on-site casting equipment have greatly sped up the building process, making hempcrete construction practical for developments beyond small, custom homes. In Europe, commercial office buildings, social housing arrays, and sports complexes have all incorporated hempcrete blocks as a key non-structural component—often with stunning results in terms of both performance and sustainability.

In the United States and Australia, the regulatory landscape is quickly adapting to meet market demand. As supply grows and construction firms gain experience, the barrier to building with hempcrete falls, paving the way for this sustainable alternative to become mainstream across the building industry in the coming decade.

Green Certification and Regulatory Acceptance

Acceptance of hempcrete construction is surging as green building certification programs like LEED, BREEAM, and the Living Building Challenge recognize its many environmental and health advantages. Many regions are now amending local guidelines and codes to specifically approve hempcrete as a compliant building product. This recognition is unlocking new funding, insurance, and marketing advantages for property owners and developers who embrace sustainable building strategies.

Beyond compliance, hempcrete’s role in documented carbon reduction, enhanced fire resistance, and superior indoor air quality is securing its place as a model material in the global race toward net-zero emissions. As certification bodies and regulatory agencies adjust standards in response to climate-driven disasters, hempcrete construction is poised to become the building industry’s material of the future.

How Hempcrete is Made: Time-Lapse from Harvest to Hemp Block

People Also Ask: Hempcrete Construction FAQ

What are the downsides of hempcrete?

Hempcrete is not load bearing in most applications, meaning it requires an internal frame made from steel or timber, which can add to costs and complexity. Its slow curing time may delay project schedules if not planned properly. Additionally, building codes in some regions do not yet fully address hempcrete, which means obtaining approvals may be challenging. However, these hurdles are steadily decreasing as the benefits become clearer and as more expertise enters the market.

Is it cheaper to build with hempcrete?

Initial costs for hempcrete construction can be slightly higher than traditional wood or block builds, primarily due to the relative novelty and limited supply. However, lower maintenance and utility bills, as well as improved durability and fire resistance, often balance out or outweigh early expenses. As supply increases and regulatory support improves, costs are expected to decrease in the coming years.

Is hempcrete stronger than concrete?

Hempcrete is not as strong as concrete in terms of compressive strength and cannot be used for load bearing on its own. However, it provides adequate strength for non-structural infill, insulation, and external walls. Its true value lies in sustainability, insulation, fireproofing, and carbon dioxide sequestration, not direct structural load support.

Can hempcrete be load bearing?

Standard hempcrete blocks are not designed for load-bearing applications, particularly in multi-story buildings. Instead, hempcrete is usually paired with a structural timber or steel frame which supports the overall load. Research is ongoing into load-bearing hempcrete products, but for now, it is best used as a high-performance, non-load-bearing wall and insulation material.

FAQs on Hempcrete Construction and Sustainable Building

What is the typical R-value of hempcrete blocks?

Hempcrete offers an R-value between 2.1 and 2.4 per inch, far exceeding most conventional masonry or concrete options.How does hempcrete construction impact indoor air quality?

Hempcrete naturally regulates humidity, prevents mold growth, and contains no toxic VOCs, supporting superior indoor air quality.Are hempcrete homes recognized under green building certification programs?

Yes, homes built with hempcrete often receive credits under certifications like LEED or BREEAM due to their energy savings, carbon reduction, and nontoxic living environment.

Key Takeaways from the Rise of Hempcrete Construction

Hempcrete offers a superior fireproof building material ideal for wildfire-prone regions.

Hempcrete construction significantly reduces carbon dioxide emissions through natural carbon sequestration.

Ongoing innovation in hempcrete blocks and techniques is shaping the future of sustainable building.

Final Thoughts: Embracing a Future Built on Hempcrete Construction and Innovation

"With every hempcrete wall raised, we are investing in safer, greener, more resilient communities — the blueprint for sustainable architecture." — Sasha Moreau, Architect

Add Row

Add Row  Add

Add

Write A Comment